A Guide to Proper Installation Procedures for Each Type of Flow Meter

- ADMIN

- Apr 26, 2023

- 2 min read

Flow meters are essential devices that measure the flow rate of fluids in various industries. However, the accuracy of flow meter readings depends on proper installation and maintenance procedures. Each type of flow meter has its installation requirements, and proper installation ensures optimal performance and longevity of the flow meter. In this article, we will provide a comprehensive guide to the proper installation procedures for each type of flow meter.

Magnetic Flow Meters

Magnetic flow meters operate based on Faraday's Law of electromagnetic induction. They have no moving parts, which makes them low maintenance devices. The installation of magnetic flow meters should be done horizontally to avoid the buildup of air pockets in the fluid. The pipe should be full of fluid, and the flow meter should be installed in a vertical or horizontal pipe with the electrodes facing the flow. The pipe diameter should be the same as that of the flow meter. If the pipe diameter is different, a reducer or an expander should be used to maintain a constant flow rate.

Vortex Flow Meters

Vortex flow meters measure the frequency of vortices that are shed by a bluff body inserted into the fluid. The installation of vortex flow meters should be done in a straight section of the pipe, with a minimum of 15 pipe diameters upstream and five pipe diameters downstream. The flow meter should be installed vertically or horizontally, depending on the application. The pipe diameter should be the same as that of the flow meter. If the pipe diameter is different, a reducer or an expander should be used to maintain a constant flow rate.

Ultrasonic Flow Meters

Ultrasonic flow meters use ultrasonic waves to measure the velocity of the fluid. The installation of ultrasonic flow meters should be done in a straight section of the pipe, with a minimum of ten pipe diameters upstream and five pipe diameters downstream. The flow meter should be installed in a vertical or horizontal pipe, depending on the application. The pipe diameter should be the same as that of the flow meter. If the pipe diameter is different, a reducer or an expander should be used to maintain a constant flow rate.

Coriolis Flow Meters

Coriolis flow meters operate based on the Coriolis effect, which is the deflection of a fluid flow caused by the rotation of the Earth. They are highly accurate and can measure both mass flow rate and density. The installation of Coriolis flow meters should be done in a straight section of the pipe, with a minimum of ten pipe diameters upstream and five pipe diameters downstream. The flow meter should be installed horizontally. The pipe diameter should be the same as that of the flow meter. If the pipe diameter is different, a reducer or an expander should be used to maintain a constant flow rate.

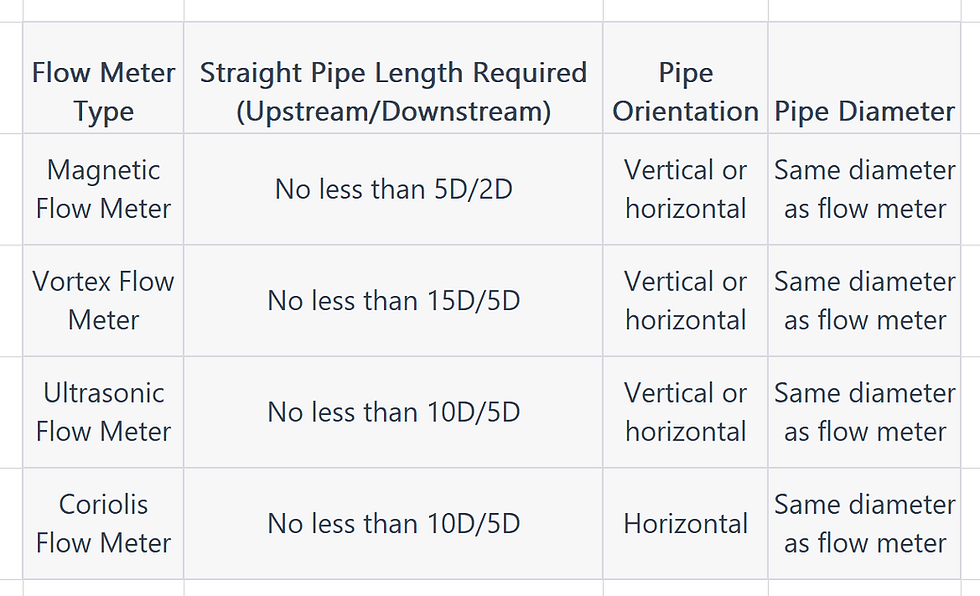

Comparison Table of Proper Installation Procedures for Each Type of Flow Meter:

In conclusion, proper installation procedures are crucial for the accuracy, performance, and longevity of flow meters.

Comentários