Making a Sound Decision: Cost-Benefit Analysis of Flow Meters

- ADMIN

- May 3, 2023

- 2 min read

Selecting the right flow meter for a specific application requires careful consideration of various factors, including accuracy, reliability, and cost. Cost-benefit analysis is a powerful tool that can help engineers and managers make informed decisions by comparing the costs and benefits of different flow meters.

When performing a cost-benefit analysis, it is essential to establish clear selection criteria that align with the needs of the application. The accuracy and range of the flow meter must be adequate for the intended use, while factors such as maintenance and operating costs must also be considered.

The initial cost of a flow meter is an important factor to consider, but it is only one component of the total cost of ownership. Maintenance costs, which can include calibration, repair, and replacement, should be factored into the analysis. Some types of flow meters, such as electromagnetic flow meters, require little maintenance, while others, such as ultrasonic flow meters, require periodic recalibration.

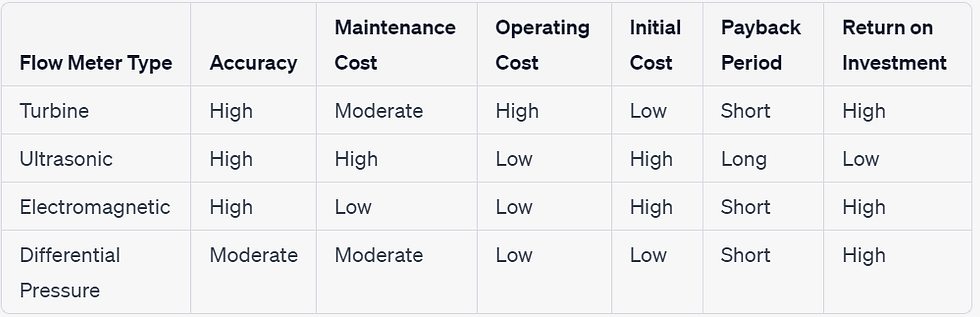

Operating costs are another key consideration. Some types of flow meters, such as turbine flow meters, require power to operate, while others, such as magnetic flow meters, do not. The cost of electricity or other energy sources should be taken into account when calculating the total operating costs of a flow meter. To perform a cost-benefit analysis, engineers and managers must also consider the payback period and return on investment. The payback period is the amount of time it takes for the cost savings from a new flow meter to equal its initial cost. The return on investment is the ratio of the net benefits to the initial investment. In general, the shorter the payback period and the higher the return on investment, the more attractive a flow meter will be. Table: Cost-Benefit Analysis for Selecting Flow Meters

The table above shows a cost-benefit analysis of different flow meter types. As can be seen, turbine flow meters have a relatively low initial cost but high operating and maintenance costs, resulting in a short payback period and high return on investment. Ultrasonic flow meters, on the other hand, have a high initial cost but low operating costs, resulting in a longer payback period and lower return on investment. In conclusion, selecting the right flow meter for a specific application requires careful consideration of various factors, including accuracy, maintenance, and operating costs. Cost-benefit analysis is a powerful tool that can help engineers and managers make informed decisions by comparing the costs and benefits of different flow meters. By establishing clear selection criteria and considering the payback period and return on investment, it is possible to select a flow meter that provides the desired level of accuracy and reliability while also minimizing total cost of ownership.

Commenti