Pumping Up Your Knowledge: An Introduction to Different Types of Pumps

- ADMIN

- Mar 27, 2023

- 3 min read

Introduction:

Pumps are essential to many industrial processes and applications, from water treatment and wastewater management to chemical processing and oil refining. A pump is a device that transfers fluids, such as liquids or gases, from one location to another. Various types of pumps are available, each with unique features, benefits, and applications. This article will provide an overview of the different types of pumps, including centrifugal pumps, positive displacement pumps, axial flow pumps, jet pumps, and specialized pumps.

Centrifugal Pumps:

Centrifugal pumps are the most common type of pump used in industrial applications. These pumps use an impeller to create a centrifugal force that pushes the fluid out of the pump and into the system. There are several types of centrifugal pumps, including single-stage centrifugal pumps, multi-stage centrifugal pumps, vertical centrifugal pumps, and horizontal centrifugal pumps. Single-stage pumps are ideal for low-pressure applications, while multi-stage pumps are suitable for high-pressure applications.

Positive Displacement Pumps:

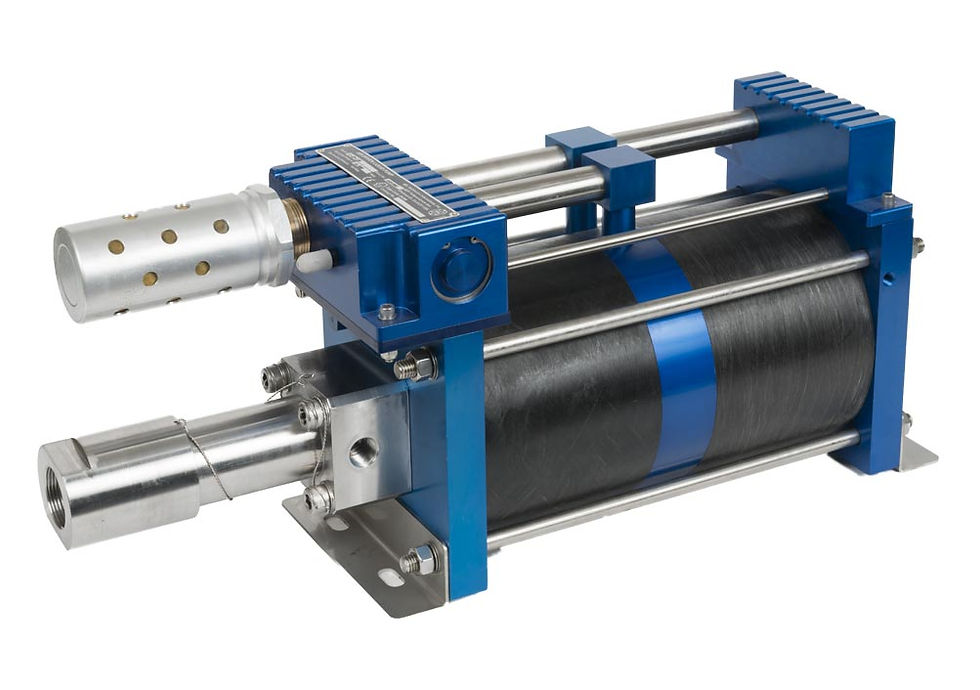

Positive displacement pumps are designed to transfer fluids by trapping and moving a fixed amount of fluid through the pump. Unlike centrifugal pumps, these pumps are not dependent on the velocity of the fluid. There are two main types of positive displacement pumps: rotary pumps and reciprocating pumps. Rotary pumps, such as gear pumps, screw pumps, vane pumps, and lobe pumps, are ideal for high-viscosity fluids. Reciprocating pumps, including diaphragm pumps, plunger pumps, and piston pumps, are suitable for high-pressure applications.

Axial Flow Pumps:

Axial flow pumps use a propeller-like impeller to create a flow of fluid through the pump. These pumps are ideal for transferring large volumes of fluid at low pressures. There are two types of axial flow pumps: propeller pumps and mixed flow pumps. Propeller pumps are ideal for transferring water and other low-viscosity fluids, while mixed flow pumps are suitable for moderate viscosity fluids.

Jet Pumps:

Jet pumps use a high-velocity jet of fluid to create a low-pressure area that draws in fluid from the system. These pumps are typically used for low-flow applications and are suitable for pumping fluids with high concentrations of solids.

Specialized Pumps:

In addition to the standard pump types, there are several specialized pumps available for specific applications. Magnetic drive pumps use a magnetic coupling to transfer fluids, making them ideal for applications where leakage is not acceptable. Air operated double diaphragm (AODD) pumps are suitable for applications where electricity is not available. Peristaltic pumps use a roller to compress a flexible tube, creating a flow of fluid through the pump. These pumps are ideal for applications where contamination is a concern.

Pump Selection Criteria:

Selecting the right pump for your application requires consideration of several factors, including flow rate, head pressure, fluid characteristics, NPSH (Net Positive Suction Head) requirements, and efficiency and operating costs. Flow rate refers to the volume of fluid the pump can transfer per unit of time. Head pressure refers to the pressure required to transfer the fluid from one location to another. Fluid characteristics, such as viscosity, temperature, and corrosiveness, can affect the type of pump required. NPSH requirements refer to the minimum amount of pressure required at the inlet of the pump to avoid cavitation. Efficiency and operating costs refer to the energy required to operate the pump and the maintenance costs associated with the pump.

Pump System Design Considerations:

Pump system design considerations include pump configuration, piping and valve design, control systems, and maintenance and serviceability. Pump configuration refers to the arrangement of pumps in the system, such as single-pump or multi-pump configurations. Piping and valve design refers to the layout of the pipes and valves in the system, which can affect the pressure drop and flow rate. Control systems can be used to regulate the flow rate and pressure of the system, ensuring that the pump operates efficiently. Finally, maintenance and serviceability considerations refer to the ease of maintenance and repair of the pump and system.

Conclusion:

In conclusion, pumps are an essential component of many industrial processes and applications. Understanding the different types of pumps and their applications can help you select the right pump for your needs. Centrifugal pumps, positive displacement pumps, axial flow pumps, jet pumps, and specialized pumps each have unique features and benefits. When selecting a pump, it is important to consider factors such as flow rate, head pressure, fluid characteristics, NPSH requirements, and efficiency and operating costs. Pump system design considerations include pump configuration, piping and valve design, control systems, and maintenance and serviceability. By considering these factors, you can ensure that your pump system operates efficiently and effectively.

Comments